Have you ever heard a loud crash from your opening and wondered what failed and why it happened?

We start this guide to demystify the parts that balance your entry and keep it moving smoothly. A broken spring often makes that crash, and quick identification helps you choose a safe fix.

Across Central Florida, we see two main Garage Door Spring Types: torsion springs mounted above the opening and extension springs along the sides. A TorqueMaster system hides springs inside a tube for a cleaner look.

We explain how each setup affects balance, noise, and stress on the opener. Our goal is to give clear visual clues so you know what you have before you call us.

Emerald Garage Door Services is family-owned, licensed, insured, and bonded. We offer 24/7/365 support, background-checked technicians, and a guarantee on parts and labor. Call (407) 788-1229 or email EmeraldGarageDoorServices@gmail.com for fast, honest help.

Key Takeaways

- Two common systems are torsion springs above and extension springs on the sides.

- Color marks and loop ends give quick ID clues before a service call.

- Right spring choice improves balance, reduces noise, and protects the opener.

- Emerald Garage Door Services provides licensed, insured, and guaranteed repairs.

- Contact us any time for same-day, expert assessment and safe replacement.

Quick ways to identify your spring system at a glance

A simple visual check at the top and sides of your opening will reveal most common spring setups. Look up first: a smooth metal tube with no visible coils usually means an enclosed system with the springs hidden inside.

If you see large coils wrapped around a bar above the entry, that signals a torsion arrangement. Cones on the ends and a connection to the metal tube confirm torsion.

Long coils running along each side of the track, paired with pulleys and cables, point to extension springs. Check the loop ends: clipped-end loops are sturdiest, double-looped are mid-grade, and open-looped are the least durable.

- Top tube smooth — enclosed spring system inside the metal tube.

- Coils on the bar — torsion springs at the top with cones on each end.

- Side coils and pulleys — extension springs along the tracks.

- Loop-end check — clipped, double, or open loops indicate durability.

Identification is step one. For safety and correct sizing, call Emerald Garage Door Services any time at (407) 788-1229. We answer 24/7/365 and can confirm your system by phone or from photos before we dispatch licensed, insured, background-checked technicians.

What garage door springs actually do and why they matter

A well-balanced lifting system makes heavy panels feel feather-light every time you open them. We explain how stored energy, cables, and drums work together so you see why proper calibration matters.

Counterbalance, torque, and tension explained

Springs counterbalance the weight of the panel. A 100-pound panel needs matching force so the operator only guides movement.

Torsion springs store rotational energy on a shaft. Cable drums at each shaft end translate that torque into a smooth lift.

Extension springs stretch along the sides and pull via pulleys and cables to offset weight. Both systems use controlled tension to hold positions safely.

How springs impact performance, noise, and opener strain

When balance is correct, movement is quiet and wear on hinges, rollers, and the opener drops significantly. An unbalanced setup causes jerky motion, louder operation, and faster part failure.

- Cycle life: Typical ranges are 10,000–20,000 cycles, so daily use affects years of service.

- Two springs: Wider or heavier panels benefit from dual springs for better balance and reduced shaft stress.

- Maintenance: Regular tune-ups test balance, lubricate parts, and inspect cables to prevent sudden failures.

We prioritize safety and longevity with precise tension and torque adjustments. Call (407) 788-1229 to schedule a balanced, quieter, more reliable system backed by our guarantee.

Understanding garage door spring types: buyer’s overview

Choosing the right lifting mechanism can save you money and reduce noisy, uneven operation.

Torsion springs mounted above the opening

Torsion springs sit above the opening. They attach to a metal shaft with cable drums and cones at each end. This setup gives smooth lifting, cleaner alignment, and often longer service life. Coated torsion options resist corrosion in humid climates and lower maintenance needs.

Extension springs along the side tracks

Extension springs run parallel to the side tracks and end in loops. Loop design affects durability: clipped and double-loop ends are stronger than open loops. This option is cost-effective for smaller or older doors but may need more frequent adjustment and louder operation.

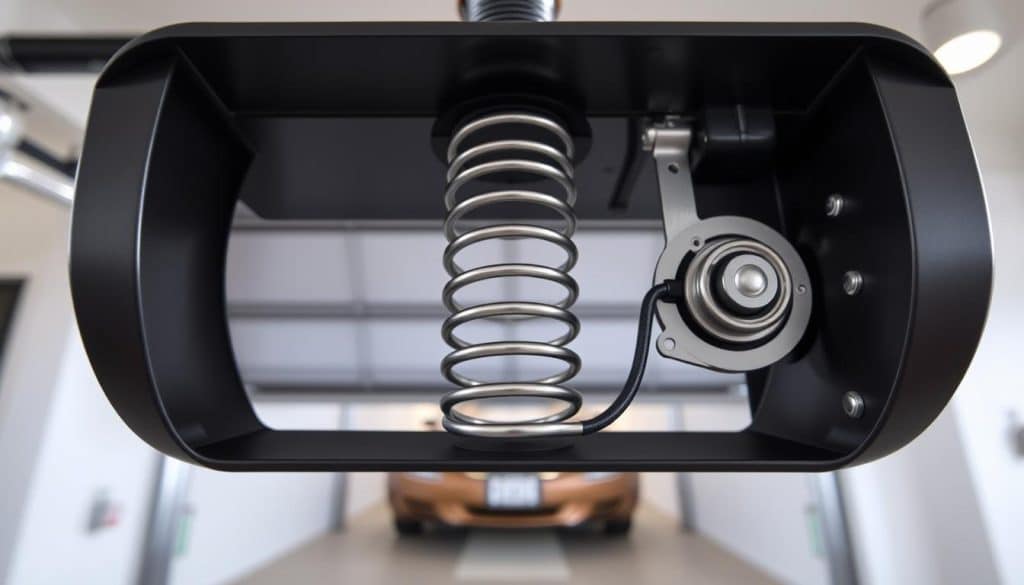

TorqueMaster enclosed systems

Enclosed systems house springs inside the shaft for a streamlined look and added containment. They offer improved safety and a tidy appearance. Converting from side-mounted extension to a shaft-based setup is a common upgrade for better balance and quieter use.

- Compare fit: door size, headroom, and weight guide the best choice.

- Maintenance: torsion usually needs less frequent tuning than extension.

- Upgrade path: conversions can improve balance and extend component life.

We provide honest comparisons and tailored recommendations. Our licensed, insured team helps you choose the right setup for your budget and safety needs—call (407) 788-1229.

Torsion springs: types, parts, and when to choose them

Many homeowners choose a torsion assembly for quieter, more balanced operation and longer service life.

Standard torsion for residential use

Standard torsion springs mount on an anchor bracket and turn a 1-inch OD shaft. This setup gives steady torque to cable drums for smooth lift and reduced opener strain.

Steel rolling-door torsion

Steel rolling door torsion is built for rolling shutters and commercial shutters. It uses heavier drums and different hardware to manage wrap and higher loads.

EZ-SET and similar quick-install systems

EZ-SET systems change measuring and service. Gaps and spacers between coils need special tools and techniques to size and tension correctly.

Cones, color coding, and shaft basics

Cones and color marks help identify left- and right-wind placement, but accurate measurement of wire size, inside diameter, and length is critical.

- Why choose torsion: smoother lift, longer cycle life with proper sizing.

- Parts you’ll see: cones, anchor bracket, tube, drums, shaft, and set screws.

- Pro tip: use two springs on wide or heavy panels for redundancy and balance.

We recommend a professional sizing and install to ensure safe tensioning and long-term reliability. Call Emerald Garage Door Services at (407) 788-1229 for licensed, insured service in Orlando, FL.

Extension springs: end types, durability, and safety cables

Extension assemblies run along each side track. They stretch and contract as the panel moves, using pulleys and cables to lift and balance the weight.

Clipped-end extension springs use a woven metal cap at the end. This design reduces stress on the coil and offers the most durable connection for high-use homes.

Double-looped end springs

Double-looped ends bend two layers of coil to form the loop. They deliver medium durability and are a common, reliable choice for standard residential use.

Open-looped end springs

Open-looped ends are the simplest. They bend a single layer and are least durable. Frequent use can lead to faster wear and more adjustments.

- Safety cables: Building code requires cables to contain a broken coil and prevent dangerous projectiles inside the garage.

- Choosing clipped-end fittings reduces downtime and extends service intervals in high-use applications.

- We inspect pulleys, rollers, hinges, and cables, then set tension for smooth, even travel during a typical service.

We install safety cables on extension systems and recommend sturdier clipped-end designs for longer life. For a quieter, safer upgrade, ask about converting to torsion. Call (407) 788-1229 for immediate, licensed, insured help.

TorqueMaster enclosed systems: pros, cons, and conversions

An enclosed torsion arrangement keeps coils out of sight and helps contain energy if a failure occurs. This design is common in homes that value a clean look and added safety.

Hidden springs inside the shaft: safety profile

Enclosed assemblies place two springs inside a metal shaft. That containment reduces exposure and helps prevent flying fragments if a coil breaks.

Containment improves protection for people and stored items during a failure. We still recommend routine inspections to catch wear early.

Service life, replacement considerations, and upgrades

These enclosed units often have shorter cycle life than higher-rated torsion options. Expect a few thousand cycles versus the longer life of heavy-duty torsion springs.

- Pros: tidy appearance and added containment.

- Cons: shorter service life and special parts.

- Upgrades: conversion to standard torsion can extend life and ease maintenance.

We service enclosed systems, carry common parts for same-day repairs, and perform conversions when customers want longer cycle life. We ensure correct shaft alignment and cable routing so panels run true and quiet.

Call us 24/7/365 at (407) 788-1229 for inspections, to replace garage door springs, or to discuss a conversion backed by our parts-and-labor guarantee.

Measuring and sizing springs the right way

Accurate measurements make the difference between a smooth lift and premature failure. We measure to match specs to weight and hardware. That reduces noise, wear, and unsafe tension.

Length and coil growth

To find true torsion length, determine the unwound length. Coils add growth when wound. For standard lifts, deduct eight coils for 7-foot doors and nine for 8-foot doors to estimate unwound length.

Wire size and coil spans

We measure wire by counting 10- and 20-coil spans. This avoids errors from paint, rust, or bent coils that fool calipers.

Inside diameter, wind, and hardware checks

Read cone markings like “P175″ for 1-3/4” or “P200″ for 2”. Identify wind by the coil end: right-wind usually sits left of center, left-wind on the right. For EZ-SET units, compress coils in segments to get accurate counts.

- Safety first: never loosen set screws to measure — our techs use proper tools.

- We check drum style, shaft, and cables so torque and tension match your panel weight.

- We verify balance after install and document specs for fast future service.

Skip guesswork — call (407) 788-1229 for professional sizing and installation backed by our guarantee.

Safety first: replacement timing and why DIY can be dangerous

When a lifting coil shows gaps or your panel moves unevenly, act fast—these are signs of imminent failure.

Signs your spring is failing or out of balance

Watch for: loud bangs, jerky motion, slower travel, a panel that won’t stay up, or a heavy feel in manual mode. Loose cables or visible coil gaps are clear red flags.

Torsion vs. extension risks and required tools

Both torsion and extension store high energy. Improper handling can cause severe injury or property damage.

- Specialized tools: winding bars, proper clamps, and secure set-screw methods.

- Never use improvised tools or try to operate the opener with a broken component.

- Replacing one on a two-spring system? Replace both to keep balance and prevent early failure.

When to call a licensed, insured professional

We recommend calling us at the first sign of trouble. We’re licensed, insured, bonded, and background-checked. We respond 24/7/365 and guarantee our work on parts and labor.

If you hear a loud bang, see gaps, or the panel won’t stay open, call (407) 788-1229 immediately.

Buyer’s guide: choosing the best spring setup for your residential garage

Selecting the right lifting assembly starts with accurate measurements and clear performance goals. We begin by measuring width, height, and actual weight so components match the load.

Fit and hardware checks: We confirm shaft diameter, drum style, cable health, and available headroom. This ensures parts and the shaft align correctly for safe operation.

Life expectancy and coatings: Cycle life typically runs 10,000–20,000 cycles. Coated options add years in humid or coastal climates and reduce corrosion for longer service.

Noise, budget, and opener pairing

Torsion springs usually run quieter and last longer. Extension springs are more affordable but need safety cables and more upkeep.

- We recommend two springs on wide or heavy panels to improve balance.

- We match a garage door opener so the motor runs inside its ideal load range.

- We present good-better-best options with clear pricing and timelines.

Final step: we provide a written estimate, parts-and-labor guarantee, and a plan to complete most jobs in one visit. Call (407) 788-1229 for a tailored quote and on-site sizing.

Conclusion

A clear final check helps you lock in a safe, long-lasting solution for your lifting system.

Identify your setup, measure precisely, and let professionals set tension for quiet, reliable performance. Correct sizing reduces opener strain and extends component life.

Torsion springs often give longer life and smoother lift. Extension solutions need safety cables and routine checks. Enclosed systems add containment but may trade off service life.

Emerald Garage Door Services is family-owned and available 24/7/365. Our team is licensed, insured, and background-checked. All work is guaranteed.

Call (407) 788-1229 or email EmeraldGarageDoorServices@gmail.com for fast, honest help in Central Florida. Schedule a proactive tune-up to prevent costly failures.

FAQ

What are the main spring systems we service?

We work with torsion systems mounted above the opening, extension setups along the side tracks, and enclosed TorqueMaster-style systems that hide springs inside the shaft. Each system has distinct parts and safety considerations.

How can I quickly identify which spring system my property has?

Look above the opening for a horizontal shaft with coiled springs (torsion). If you see long springs running parallel to the tracks at the sides, those are extension springs. If the shaft is solid and smooth with no visible coils, it’s likely a TorqueMaster enclosed system.

What do springs actually do and why do they matter?

Springs counterbalance the door’s weight so the operator can lift and lower safely. Proper torque and tension ensure smooth movement, reduce noise, and prevent undue wear on the opener and hardware.

How do springs affect noise and opener strain?

Worn or improperly balanced springs increase vibration and noise. They force the opener to work harder, shortening its service life and risking motor failure. Correctly matched springs keep operation quiet and efficient.

When should I choose torsion springs over extension springs?

Torsion springs generally offer better balance, longer cycle life, and quieter operation for residential installs. Extension springs can be more economical and fit some track layouts, but they require safety cables to reduce risk.

What is unique about TorqueMaster or enclosed shaft systems?

TorqueMaster hides the coils inside the shaft for a cleaner look and improved safety. They can be trickier and costlier to service or convert, but they reduce exposed spring hazards in family homes.

How do we measure and size springs properly?

We measure unwound length, count coils or use 10- and 20-coil measurements for wire size, and check inside diameter against cone markings. Wind direction (right vs. left) must be identified to match torsion setup.

What signs show a spring is failing or out of balance?

Look for uneven travel, jerky movement, loud bangs at opening, cables that hang slack, or difficulty operating the opener manually. These indicate imminent failure and need prompt attention.

Are DIY spring replacements safe for homeowners?

No. Springs store high energy. Improper handling risks severe injury and property damage. We recommend a licensed, insured technician from Emerald Garage Door Services for replacements.

How do different end types on extension springs affect durability?

Clipped-end springs offer sturdier connections and longer life. Double-looped ends provide moderate durability. Open-loop ends are the most basic and usually wear faster under heavy use.

What should I consider when choosing a replacement spring setup?

Base decisions on opening size, weight, height, and existing hardware. Consider cycle life ratings, corrosion-resistant coatings, noise levels, and how the setup pairs with your opener.

How long do standard residential torsion springs usually last?

Typical residential springs last from 7,000 to 20,000 cycles depending on quality and use. Higher-cycle springs and proper maintenance extend service life significantly.

Can TorqueMaster systems be converted to standard torsion?

Yes, conversions are possible but require careful assessment. We evaluate safety, shaft condition, and cost to determine whether conversion or repair is the better option for your property.

What safety hardware should accompany extension springs?

Extension setups must have safety cables running inside the springs to prevent loose components if a coil fails. We also recommend regular inspections and professional maintenance.

How do cones, color codes, and shaft placement help identify torsion springs?

Cones often include size markings and color bands that indicate wire and diameter specs. Shaft placement and cone types help technicians match replacement springs accurately for proper balance and torque.

When should I call Emerald Garage Door Services?

Call us if you notice imbalance, sudden noise, visible gaps in coils, broken springs, or if an opener struggles. We provide safe diagnostics, accurate measurements, and insured replacement in Orlando and surrounding areas.